Operating at the cutting edge is nothing new for Acutec Precision Aerospace, but staying there requires more than advanced machines. It demands a culture built on problem‑solving, resilience, and deep collaboration with expert partners—especially when machining the toughest materials in aerospace.

Mastering High‑Precision, High‑Stakes Manufacturing

Acutec specializes in complex, tight‑tolerance components for aerospace and defense, machining everything from actuation parts to hot‑side engine components. Working with high‑temperature nickel alloys and tolerances as tight as ±0.00025 inches means there’s no room for error. That’s why the company leans heavily on its long‑standing partnership with Sandvik Coromant.

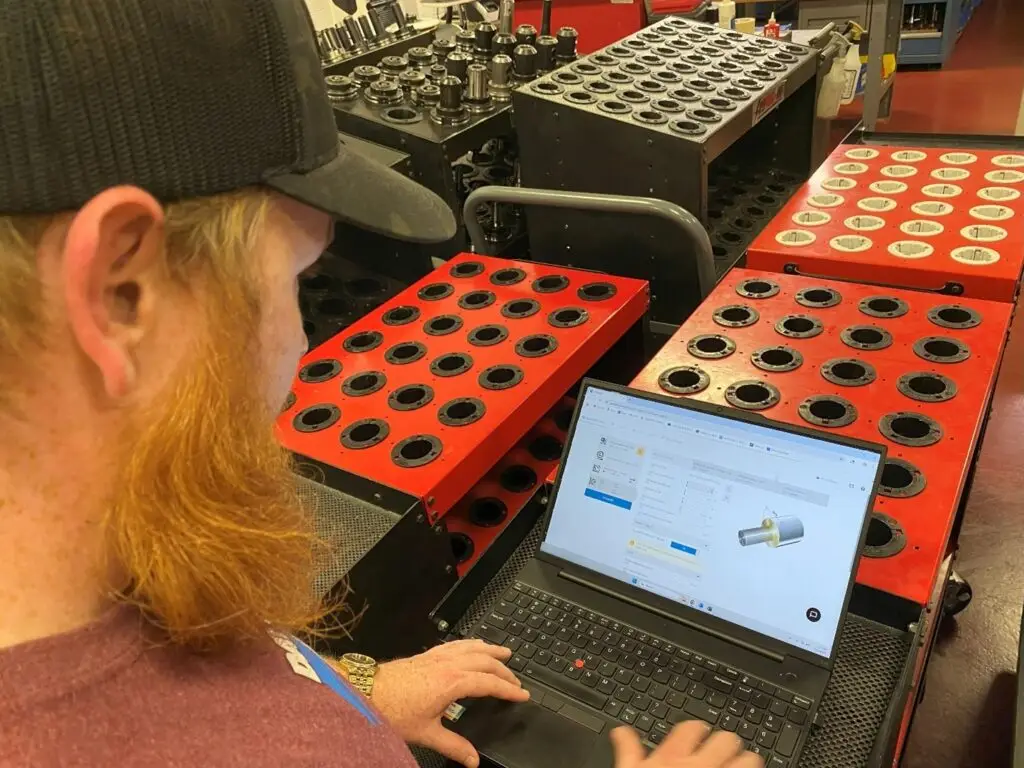

Weekly collaboration, technical support, and real‑time tooling insights help Acutec tackle difficult features, optimize processes, and maintain the tooling inventory needed to keep production moving.

Tooling Innovation That Drives Performance

Sandvik Coromant’s turning inserts play a central role in Acutec’s success. The standout is the S205 CVD finishing grade, which has transformed performance in Acutec’s highly automated machining cell. Running Inconel 718 parts with minimal human intervention, the cell recently hit 95% uptime—a testament to the stability and wear resistance of the S205.

Before adopting S205, Acutec tested dozens of insert grades. The new grade not only extended tool life but also ensured consistent precision, eliminating rework and enabling true lights‑out machining.

Solving the “Un‑Machineable”

When Acutec faced a new, extremely abrasive coating on helicopter rotor components—“like trying to machine concrete”—traditional tooling failed fast. Sandvik Coromant stepped in with a custom PCD insert solution, boosting tool life from 5–6 parts per edge to nearly 100. A dramatic leap that unlocked real production viability.

Automation, Flexibility, and Faster Changeovers

Acutec also leverages Sandvik’s Coromant Capto modular tool‑holding system to reduce setup times and increase flexibility. In one application, Capto helped triple throughput, freeing capacity for additional jobs and enabling rapid changeovers in automated cells.

A Partnership Built on Knowledge and Continuous Improvement

Beyond tooling, Sandvik Coromant supports Acutec with preproduction planning, process optimization, and extensive on‑site training. Their six‑month training program helps new employees understand metal‑cutting fundamentals, make smarter tooling decisions, and improve retention—strengthening Acutec’s workforce from the ground up.

Driving Innovation Together

The Acutec–Sandvik Coromant partnership is more than a supplier relationship. It’s a shared commitment to innovation, problem‑solving, and pushing the boundaries of what’s possible in aerospace manufacturing. From day‑to‑day troubleshooting to long‑term process development, the collaboration continues to fuel Acutec’s ability to operate at the forefront of the industry.

Read the full article HERE (Page 41).