Critical Parts.

Better Process.

Always Precise.

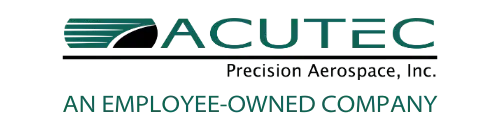

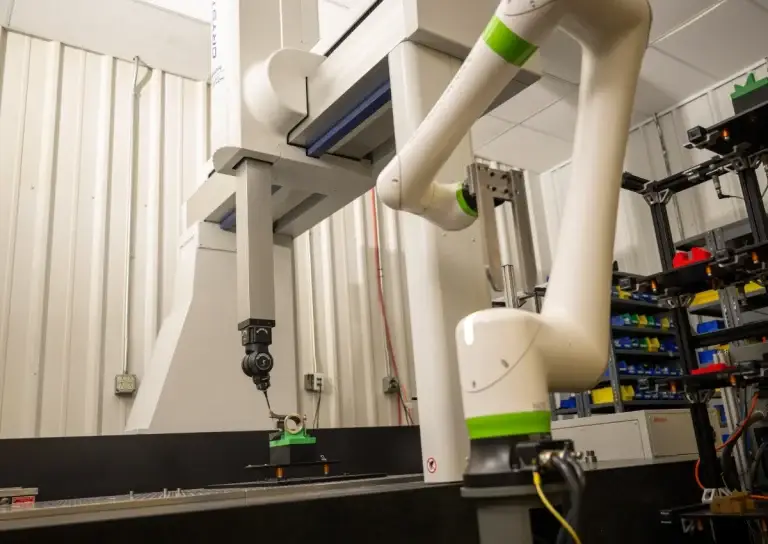

Zero Defect Planning

Zero defects is a philosophy that focuses on the importance of accuracy and precision from the outset. This approach is dedicated to eradicating flaws, enhancing the quality of products or services, and diminishing expenses related to inefficiencies and errors.

- AS13000 8D problem-solving with live NC collections and alerts

- AS13001 Supplier self-release source inspection program

- AS13002 Capacity-based inspection frequency with electronic SPC at machine

- AS13003 Measurement systems analysis with gage lab and in-house calibration

- AS13004 Closed-loop PFMEA and process-planning

- AS13006 Process control methods with integrated process change request system