In the rapidly evolving landscape of manufacturing, the concept of Industry 4.0 has been at the forefront of technological advancements. However, forward-thinking companies like Acutec are now setting their sights on the next phase, Industry 5.0, which emphasizes a truly collaborative environment between humans and robots to achieve optimal efficiency and productivity. With a focus on meeting increased customer demand for a business jet engine component and preparing for luck with the projected rise in business jet production, Acutec is undergoing a transformative journey to embrace Industry 5.0 principles. As part of this initiative, they are seeking a third-shift machinist to join their innovative team.

Acutec has been manufacturing this business jet engine component since 2008 and has continuously improved the process. This is one of over 400 different components Acutec makes for business jets, half of which are on active long-term contractual production agreements. The process today is already 16% faster than it was in 2008, with improved quality, meeting new stringent AS13100 specifications (a quality specification specifically developed for aircraft engine components in 2021).

To address the increased customer demand for this component, Acutec is ramping up its production capacity. To achieve a 50% increase in throughput, the company is strategically integrating automation into its manufacturing processes and moving machines, in order to utilize existing equipment 160 hours a week with 80 hours a week staffing. In doing so, Acutec aims to optimize production efficiency without compromising quality.

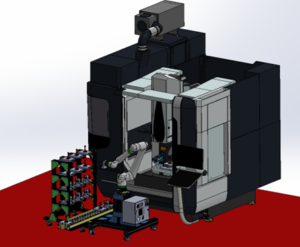

As part of its expansion plans, Acutec is actively looking to hire a third-shift machinist to join its collaborative environment. The machinist in this dedicated cell, consisting of a DMG Mori DMU50 mill and two NL2000 lathes, will have the opportunity to learn both milling, turning, and G-code as a path to advancement within the company, and the support of a full-time night-shift trainer on staff. By working closely with the FANUC robotics interface and our in-house automation team, the third-shift machinist will contribute to the achievement of increased throughput and help meet the rising customer demand. This night shift position is one of the many varieties of open positions at Acutec. See Figure 1 for a glimpse into the potential cell layout.

Figure 1

Acutec’s transition from Industry 4.0 to Industry 5.0 exemplifies their commitment to innovation and meeting the evolving needs of their customers. By hiring a third-shift machinist, Acutec demonstrates its dedication to leveraging human expertise alongside automation to drive success in the era of Industry 5.0.

For more information about Acutec’s manufacturing capabilities, available positions or to apply for the third-shift machinist position, please visit our careers page.

###

About Acutec Precision Aerospace, Inc.

Founded in 1988, Acutec Precision Aerospace, Inc. is an award-winning, family and employee-owned manufacturer of critical components and subassemblies for aerospace and defense applications. Acutec is a subcontractor both directly and indirectly for numerous platforms including but not limited to; fixed wing, rotary wing, space, power generation, and naval programs. These components are made from a diverse set of metals including inconel, titanium, and novel materials.

Acutec provides the services that customers require to meet their aerospace and defense commitments by providing: CNC Milling, CNC Turning, EDM, Grinding, Assembly & Knitting, and NDT & Finishing. Acutec partners with its suppliers, with full documentation, engineering, and supply systems (JIT) support. With two locations in Northwestern Pennsylvania and one in South Carolina, Acutec runs the newest in CNC machinist equipment, is AS9100D and IS9001 certified, and has multiple NADCAP certifications.