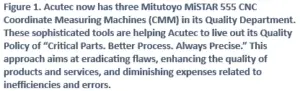

Acutec has acquired its third Mitutoyo MiSTAR 555, a state-of-the-art CNC Coordinate Measuring Machine (CMM) for its Quality Department. The first MiSTAR 555 at Acutec arrived in March of 2023, and the investment in this trio of CMMs has enhanced quality control processes and streamlined production operations. Quality Director, John Vogan, said, “The primary reasons we acquired these CMMs were the size (it’s smaller), it’s more suitable for on-floor applications, conducive to automation, flexibility, cost, and its touch and scanning probe capabilities.” These reasons provide Acutec with enhanced efficiency through faster inspection cycles, reduced overall lead and setup times, increased productivity, and maximized throughput.

A standout feature of the MiSTAR 555 is its ability to precisely scan parts, as well as take touch points, offering flexibility in measurement techniques to suit various inspection requirements. “Traditionally, we’ve used touch probing technology when checking parts on a CMM,” said Vogan. “With this approach, the probe is programmed to take a series of discrete touches at specific locations on the part. CMMs with scanning technology make continuous contact with the part, taking a significantly larger number of data points and detecting possible non-conformances that could be missed by the limited number of points you get by just touching the part at limited, discrete locations.”

Moreover, the MiSTAR 555’s advanced programming capabilities enable it to run programs at higher speeds, both in movement and measurement. “When programmed correctly, scanning CMMs like our MiSTAR 555s can operate much faster,” Vogan said.

Being compact in size, the MiSTAR 555s have been easily integrated into the manufacturing floors at Acutec’s Meadville and Saegertown facilities. Vogan said, “For areas with less working space, purchasing MiSTAR 555s makes the most sense.” He explained that Acutec manufactures a wide variety of aerospace parts, many of which are small in size and do not require large CMMs. For example, Acutec makes shims, which are small rotor components of helicopter propellors that are most efficiently inspected with a compact machine like the MiSTAR 555. Large CMMs typically allow only front loading. In contrast, the open structure of the MiSTAR 555 lets operators load parts from three sides.

Vogan said the MiSTAR 555 is well-suited for on-floor applications because its systems are resistant to the oil and debris commonly found in a manufacturing environment. He said all these features made it easy to integrate the MiSTAR 555 into Acutec’s automated manufacturing cells in Meadville and Saegertown.

Quality Inspector jobs are available in Acutec’s Meadville and Saegertown facilities. Entry-level Quality Inspectors will acquire in-house training to develop the necessary skills to perform inspection at all stages of production. Skilled Quality Inspectors must be able to follow work instructions, utilize databases and complex measurements, and complete inspection reports.

“I have been at Acutec just under a year, but I have done inspection all my life,” said Peggy Hall, In-Process Inspector. “I was looking for a job where I would have the opportunity to work with different measuring tools like the MiSTAR 555, and at Acutec, I have that! I like that there is variety.”

###

About Acutec Precision Aerospace, Inc.

Founded in 1988, Acutec Precision Aerospace, Inc. is an award-winning, family and employee-owned manufacturer of critical components and subassemblies for aerospace and defense applications. Acutec is a subcontractor both directly and indirectly for numerous platforms including but not limited to; fixed wing, rotary wing, space, power generation, and naval programs. These components are made from a diverse set of metals including inconel, titanium, and novel materials.

Acutec provides the services that customers require to meet their aerospace and defense commitments by providing: CNC Milling, CNC Turning, EDM, Grinding, Assembly & Knitting, and NDT & Finishing. Acutec partners with its suppliers, with full documentation, engineering, and supply systems (JIT) support. With two locations in Northwestern Pennsylvania and one in South Carolina, Acutec runs the newest in CNC machinist equipment, is AS9100D and IS9001 certified, and has multiple NADCAP certifications.