Milling

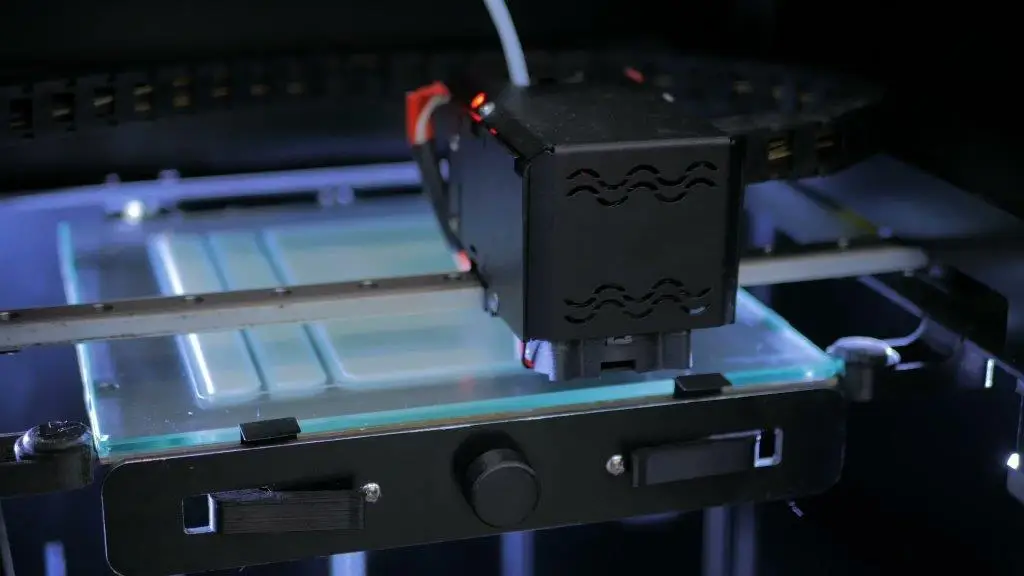

Acutec is established as a premier long and short run part milling facility in northwestern Pennsylvania and the world.

All Acutec milling centers are equipped with Renishaw touch probes. We can machine in four- and five-axis and machine parts from .250 inches diameter to 20 inches diameter. Our horizontal machining centers have automatic pallet changers.

Tools are gaged and set with Speroni Optical Presetters and offsets are uploaded to a local server. All mill programs are stored and transmitted via a shop-wide DNC and ethernet connection system.

102 CNC Milling Centers

- (1) DMG Mori 125 U DMC 80 FD

- (1) DMG Mori NH-4000DCG

- (2) NHX-4000 5 RPS (Palletized)

- (2) NHX-6300 24 LPP (Palletized)

- (1) DMC 80 FD Mill Turn

- (10) DMG Mori DMU50 10 RPS (5-axis Palletized)

- (3) DMG Mori NH-5000DCG

- (15) DMG Mori NH-6300DCG

- (1) DMG Mori SH-400

- (1) DMG Mori SH-63

- (1) Mazak HCN-6800

- (13) DMG Mori NMV-5000 (5-axis)

- (2) Mazak Variaxis i500 (5-axis)

- (13) Mazak VCN-510C / 530

- (3) Mazak VCU-400A 5X (5-axis)

- (11) DMG Mori CMX1100

- (1) DMG Mori DV5100

- (2) DMG Mori NV-4000

- (6) DMG Mori NV-5000

- (13) DMG Mori NVX-5000 series

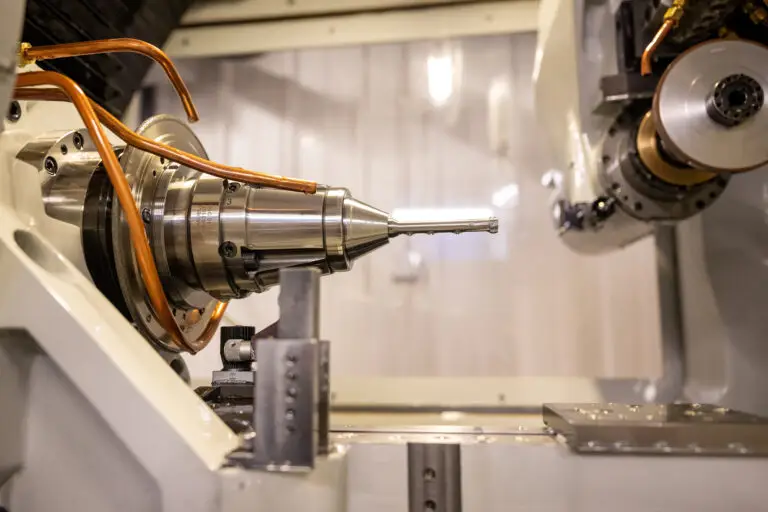

Turning

Our CNC Turning Centers support large-diameter turning at close tolerances. Extensive resources of tooling, gaging, and quality machines enable us to run at maximum productivity and maintain unmatched quality.

We have turning capabilities from .250″ diameter up to 16.5 inches in diameter. For turning up to 1.625 inches in diameter we can turn up to 27.5 inches long. We can bar feed material up to 3 inch diameter and 12 feet long. Many of our turning centers are set up to run in cellular arrangements. We also have turning centers with live tooling and dual turrets for maximum productivity.

We can turn within .0005″ tolerance and with finishes of 16√. For parts under .0005″ tolerance, we employ our own CNC honing and grinding in-house. All programs are stored and transmitted via a shop-wide DNC and ethernet connection system.

152 CNC Turning Centers

- (2) Mazak i-200STW

- (1) Mazak i-300ST

- (4) Mazak i-400ST

- (2) DMG Mori CL2000BT

- (3) DMG Mori Dura Turn 2030

- (3) DMG Mori NL-1500

- (2) DMG Mori NL-1500Y

- (10) DMG Mori NL-2000

- (10) DMG Mori NLX-2000Y

- (8) DMG Mori NL-2500

- (11) DMG Mori NLX-2500Y

- (4) DMG Mori NL-3000

- (7) DMG Mori NLX-4000

- (3) DMG Mori SL-250

- (2) DMG Mori SL-300

- (1) Mazak Dual Turn 20

- (3) Mazak MPLX-6100Y

- (24) Mazak QT-100

- (1) Mazak QT-20

- (23) Mazak QT-200

- (2) Mazak QT-200Y

- (13) Mazak QT-250

- (1) Mazak QT-300

- (1) Mazak QT-350

- (5) Mazak QT-6

- (6) Okuma V760EX

- (4) Tsugami B0386-|||

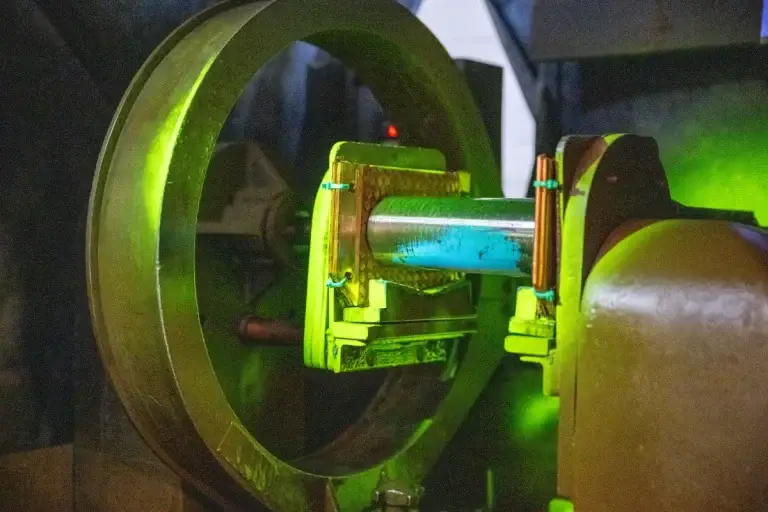

Grinding

Acutec has the ability to perform precision grinding and honing operations, thanks to its highly specialized CNC and Manual equipment.

Grinding Capabilities

- Centerless grinding capabilities of .0001″ total

- Cylindrical grinding capabilities of .00005” total

- Out of Round / Thread Grinding

- Single and Double sided lapping with capabilities of holding flatness and parallelisms of .0001 and finishes of 4√

- Surface grinding capabilities of .0002″ flatness

- Bore honing capabilities

ID/OD Grind Equipment (CNC and Manual)

- (1) Kellenberger K-100

- (1) Kellenberger KEL-Vista

- (1) Kellenberger KEL-Varia

- (1) Okamoto OGM-012-36

- (1) Okamoto OGM-8-20

- (1) Harig Model 612 W/ Ded-Tru

- (1) Cincinnati 2M2H1Z-101

Bore Honing Equipment (CNC and Manual)

- (3) Sunnen MBB-1660

- (1) Sunnen SV-25 (Vertical Hone)

- (1) Sunnen ML-5000-D (Production Hone)

Surface Grinding and Lapping

- (1) Okamoto ACC16-32

- (1) Lapmaster Model 36 (Single Plate)

- (1) SpeedFam 12B (Double Plate)

EDM

Acutec has a large EDM (Electric Discharge Machining) department that can be used to meet complex requirements and metal removal on an array of different materials.

EDM Capabilities

- Complex 3D solid modeling and electrode extraction from scratch or using customer supplied model

- Programming and machining of electrodes using 3, 4 and 5 axis CNC mills

- Programming and NC file generation for wire EDMs using customer supplied models

- 3R work holding system utilized on every machine

- All electrodes and fixtures are modular and interchangeable on every machine using the 3R work-holding system. This allows parts to be run on any machine without the need for additional setups

CNC EDM Equipment

- (2) Makino EDBV3 5 Axis Hole Popper

- (2) Makino Duo 43 Wire EDM

- (2) Makino U3 H.E.A.T. Wire EDM

- (2) Makino EDAF3 H.E.A.T. Ram EDM

- (3) Makino EDAF3 Ram EDM

- (2) Makino EDAF2 Ram EDM

- (1) Mitsubishi EA8 Ram EDM

- (1) Makino F5 HS Mill (Graphite Mill)

- (1) DMG Mori Dura Vert 5100 Mill

Recast Removal

EDM recast layers are removed per customer specification on an in-cell Mori Seiki vertical mill

Post-Processing

Finishing (Deburr)

Acutec’s finishing department is staffed with highly skilled technicians trained in burr detection and removal through the use of precision tooling and detailed visual instructions. We are capable of deburring the most complex fluid manifolds in the industry.

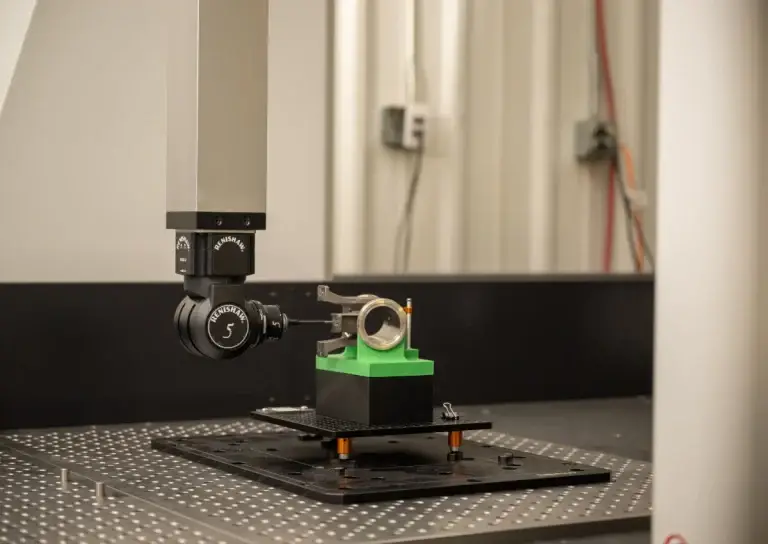

Finishing Capabilities

- (14) 10X-50X Microscopes

- (16) Fiberoptic Backlights

- (1) Digital Microscope

- (1) Digital Borescope

- (17) Dynabrade Downdraft Tables

- (20) High Speed NSK rotary spindles

- (2) Fully automated robotic deburring systems

- (1) Rotary Pin Deburring System

- (2) Giant Vibratory Tumblers

- (1) Empire Media Blast Cabinet

Coatings

Dry Film Lube

NADCAP approved

- AS 5528

- AS 5272 TYPES I, II, & III

- AS 1701

- MIL-PRF-46010

- MIL-L-46010

- MIL-L-23398 TYPES I & II

- 5D1-2961 CLASS 1

- BPS 4310

Epoxy Coating

BLUE COAT:

- BPS 4465

- PRC-S-0109

SCOTCHCAST:

- PRC-S-0246

Paint

PRIMER:

- MIL-PRF-23377 TYPE 1 CLASS C2

- MIL-PRF-23377 TYPE 1 CLASS N

- MIL-PRF-23377 TYPE 2 CLASS C2

- MIL-PRF-85582 TYPE 1 CLASS C2

- MIL-PRF-85582 TYPE 1 CLASS N

- DOD-P-15328

- TT-P-1757

- BPS 4451

TOP COAT:

- MIL-PRF-85285 TYPE 1 CLASS H

- (AMS-STD-595 COLOR: 16440, 17925, 17875, 13538, 11136, 36440, 37038, 34084, & GLOSS CLEAR)

- MIL-PRF-22750 TYPE 2 CLASS H GRADE A

- (AMS-STD-595 COLOR: 16440, 37038, GLOSS CLEAR)

- BPS 4427

- BPS 4464

- IFC30-116-02

Coatings Equipment:

- (3) GLOBAL INDUSTRIES OPEN FACE PAINT BOOTHS W/ AIR MAKE UP UNIT

- (1) CLO-MET ENCLOSED PAINT BOOTH

- (2) DEIMCO POWDER COAT BOOTHS

- (7) GRIEVE OVENS

- (4) EMPIRE BLAST CABINETS

- (3) FISCHERSCOPES (COATING THICKNESS GAUGE)

- (1) MASKING PLOTTER

Chemical Processing

Chem-Film

NADCAP approved

- MIL-DTL-5541 TYPE 1 CLASS 1A and 3

- FED-STD-141

- ASTM-B117

- Film Appearance: Section 6.8

- Adhesion testing: ASTM-D-3359 Procedure A, METHOD 6301

- Electrical Contact Resistance: MIL-DTL-81706

- Corrosion Resistance: ASTM-B-117 (168 HR)

- Material types used: Alodine 1200S

Nital & Titanium Etch

NADCAP approved

- Spec: P-105-48 (CLASS “B” ONLY)

Passivation

NADCAP approved

- ASTM A967/AMS 2700 based, Nitric 1, 3 and 4, and Citric Acid

Quality Assurance

Intrinsic Quality

When a part is processed at Acutec, a feature-based inspection criteria guide is also created for every dimension at every operation. Every machine workcenter is equipped with surface plates and the necessary inspection equipment to allow operators to perform consistent and reliable in-process inspection. At Acutec, quality is not a department, it’s an integral part of what we do.

Continuous Improvement Philosophy

At Acutec, every single employee is dedicated full-time to continuous improvement projects. We don’t employ button-pushers. Our people–at all levels of the organization–think. We recognize that we are in competition with the world every single day. Using the lean manufacturing philosophy, Six Sigma methodology, AS9100D and our ISO 9001:2015 and NADCAP certifications, we are able to drive down costs, improve quality, and reduce lead times through all areas of our business. This allows us to provide you with high-quality components in less time and at a lower cost than the competition.

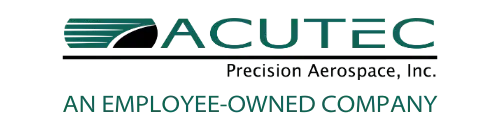

5 Inspection Labs

- 10 CNC CMMs (7 manual CMMs)

- Off-line CMM programming

- Point-cloud capability

- Fiber-optic visual inspection

- TESA-SCAN OD scanning

- In-house calibration, gage R&R

- uniPoint quality system

- Qualified internal source-inspectors

- QIF standard data exporting

Operator Inspection Point of Use

- Electronic SPC capture

- Additional manual CMMs

- Comparators

- Job-specific gages

- Microscope visual inspection

- Qualified operator self-inspection

Inspection Equipment

- (19) AIR GAGING Air Gage

- (1238) AIR GAGING Air Ring

- (19) AIR GAGING Air Snap

- (13) AIR GAGING Master Setting Disc

- (13) COMPARATOR

- (1) IMAGE QUALITY INDICATOR

- (467) Bore Gage

- (10) BORESCOPE

- (23) Sunnen Gage

- (704) CALIPERS

- (478) FUNCTIONAL GAGE

- (448) GAGE BLOCK

- (24) HEIGHT GAGES

- (1200) INDICATOR

- (60) INTERTEST

- (37) JOHNSON GAGE

- (52) MAHR GAGE

- (5) Micro-Hite

- (2447) Mics

- (79) PROFILOMETER

- (140) SPLINE GAGE

- (249) SURFACE PLATE

- (1432) THREAD PLUG

- (1510) THREAD RINGS

- (1) Thread Roller

- (36) FEDERAL GAGE

20 Coordinate Measuring Machines

- (1) CMM BH 305 MANUAL

- (1) CMM BRT707

- (1) CMM BRTA910

- (2) CMM CRT-AC776

- (3) CMM CRT-AC9106

- (1) CMM CRTAS776

- (1) CMM CRT-AS776

- (1) CMM CRTAS9106

- (1) CMM FLOOR CMM

- (1) CMM GAGE 2000

- (1) CMM MACHV9106B

- (2) CMM MIT B504B MANUAL

- (1) CMM MIT BH303 MANUAL

- (1) CMM QVT1-X606P1L-D

- (1) CMM REFLEX 343

- (1) CMM TESA SCAN

Assembly and Testing

Acutec’s assembly team is trained on a variety of component installations and sub-assemblies as well as testing procedures ranging from high pressure testing, breakaway torque testing, hardness, conductivity and, balancing.

Assembly Capabilities

- Threaded Inserts (Helical, key lock, and swage style)

- Fluid Plug (Lee Plugs and Lee Check Valves)

- Press Fit Installations

- Thermal Fit Installations

- Bearing Swaging and Staking

- Rosan Fitting Installation

- Adhesive Bonding

- Sealant Application

Assembly Equipment

- (4) TOX-PRESOTECHNIK 16kN Toggle Presses

- (1) 30-Ton Hydraulic Press

- (2) Arbor Presses

- (1) Custom Enerpac Hydraulic Reverse Draw Press

- (4) Electric Thread Insert Prewinders

- (1) Pneumatic Thread Insert Prewinder W/ Belt Feed

- (1) Grieve AB-550

- Various Thread Insert Tools Ranging from 2-56 to ½-13 and Metric

Sizes

- Job Specific Custom Assembly Tooling and Work Holding

- Variety of Standard Machine Shop Hand Tools

Testing Capabilities

- Hydrostatic / Pneumatic Testing up to 6000 PSI

- Balancing

- Hardness Testing

- Conductivity Testing

- Break Away Torque Testing

- Proof Load Testing

Testing Equipment

- (2) Wilson Rockwell Series 2000

- (2) MaxPro Hydrostatic Testing Systems

- (1) Custom Pneumatic Testing System

- (1) Loadstar RSB2 2200lb load cell

Non-Destructive Testing

Magnetic Particle Inspection

Acutec has two magnetic particle inspection lines using a Magnaflux Wet Horizontal unit, Model H-700 with 12 ¼ inch inner diameter, 5 turn coil, full wave direct current and a Magnaflux demagnetizing Unit Model SB 911, alternating current. The process is a wet continuous one.

- NADCAP and Boeing certified

- ASTM E1444 based, Full wave DC Wet

- Fluorescent to 6000 Amps capable

- Two Level II inspectors and a Level III inspector

Fluorescent Penetrant Inspection

Acutec has two fluorescent penetrant lines, using Type 1 method A (water wash) and D (Post Emulsified Penetrant) to sensitivity levels 2, 3 and 4.

- ASTM E1417 based.

- Two Level II inspectors and a Level III inspector

- NADCAP and Boeing certified

MPI Approved By:

- Boeing

- Bell Helicopter

- Sikorsky

- Parker Hannifin Corporation

- Smiths Industries Aerospace

- Aircraft Braking Systems

- Curtiss-Wright Corporation

- Lord Corporation

Hardness and Conductivity Testing

Acutec maintains equipment in multiple departments for hardness and testing of proper coatings adhesion and for traceable serialized hardness and conductivity data depending on the application.

X-Ray

- NADCAP approved

- Computed radiography (CR)

- Technique: 220KV with dual focal spots 1MM, and 3MM

- Customer approvals: ES-2001, P-106-19-3

- Limitations: metals with a thickness of .250″ or greater

Materials

Acutec purchases and manages inventory of a wide variety of Aerospace bar stock as well as casting and forgings through key distributors and suppliers. Sourcing decisions are value-based, considering quality, delivery, and cost. Our three Niton guns verify that we have the right material 100% of the time.

Nickel Alloys

- Hast X

- Inco 625

- Inco 718

- Inco X750

- Haynes 230

- Invar 36

- Alloy 20

- Monel 400

- Monel K-500

- C276

- A286

- 4750 NI/FE

Titanium Alloys

- 6AL-4V

- 6AL-4V ELI

- 3AL2.5V

- CP70

Cobalt Alloys

- L601

- Haynes 188

- Waspaloy

- Rene 41

- Stellite 6B

3D Printed Metals

- Customer proprietary

Aluminum Alloys

- 2011

- 2014

- 2017

- 2024

- 2618

- 6013

- 6061

- 6082

- 7050

- 7075

- 7175

Magnesium Alloy

- AZ61A

Alloy Steel

- 4130

- 4140

- 41L50

- 4340

- 52100

- 8620

- 9310

- 300M

- Aermet 100

Carbon Steel

- 1018

- 1026

- 1045

- 1117

- 1137

- 1141

- 12L14

- 1215

Stainless Steel

- 303

- 304

- 309

- 310

- 316

- 321

- 347

- 410

- 416

- 420

- 430

- 431

- 440

- 440C

- 455

- 465

- 17-4

- 15-5

- 13-8

- Greek Ascoloy

- Nitronic 50

- Nitronic 60

Bronze/Copper/Brass/Beryllium

- C110

- C172

- C360

- C544

- C623

- C630

- C642

- C647

- C655

- C673

- C729

- C922

- C932

- C955

- Ampco 18

- Ampco 45

Engineered Plastics

- Delrin

- Teflon

- Torlon

- Delrin

- Nylon

- Peek

- Polycarbonate

- Vespel

- Phenolic Laminates

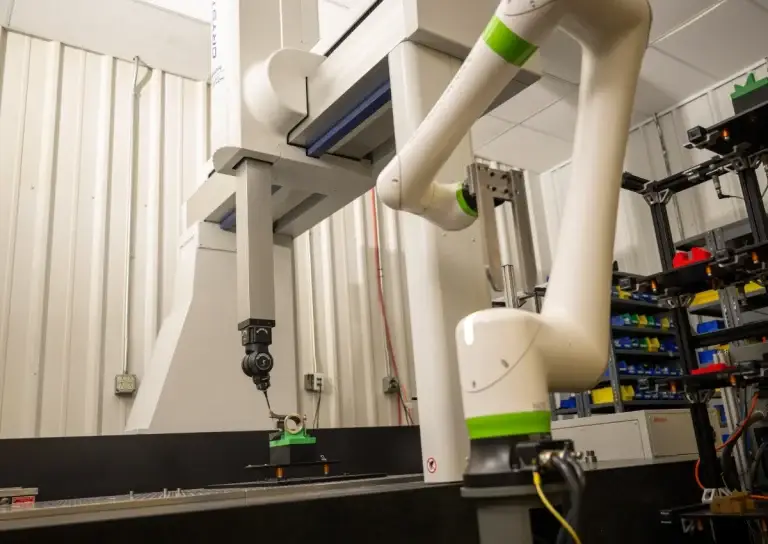

Metal Joining

- Tube bending & welded tube assembly

- GTAW Welding (Precision TIG)

- NADCAP approved

- 2 Lincoln Square Wave Tig 355 manual welding machines

- 1 Lincoln Aspect 375 smart welder

- 1 Weldlogic AWS-150 semi-automatic welding lathe with programmable indexer

- 1 Jetline Automatic welding lathe with programmable indexer, wire feed and ALC. Powered with a Miller Maxstar 350

- All welding fixtures are designed and manufactured in house

- All welding programs are created in house

- Specialized in the welding of Inconel, Hast-X and all grades of Stainless steel

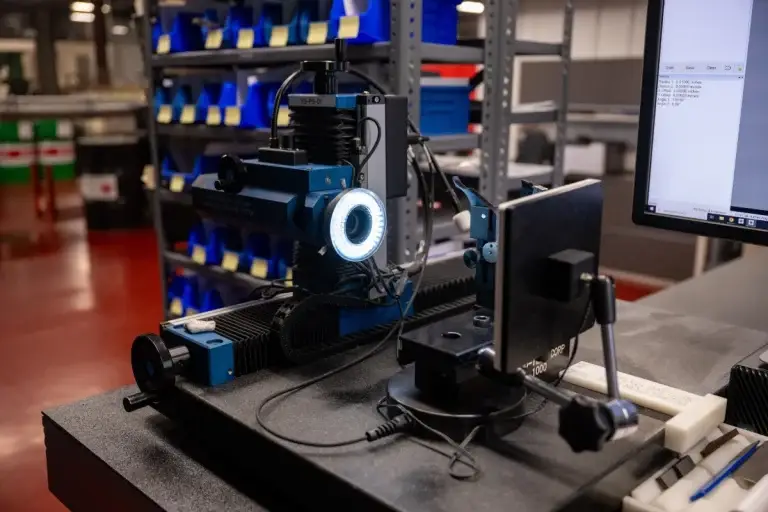

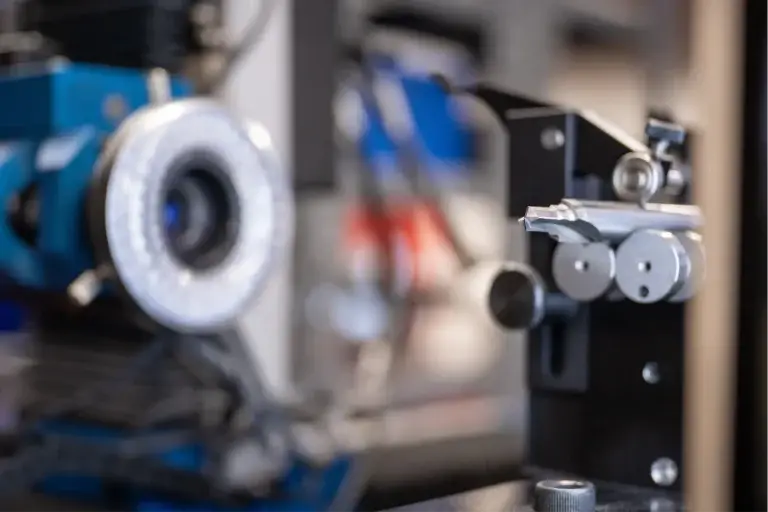

Tool Grinding

Acutec has the ability to grind (manufacture) and regrind carbide or HSS cutting tools in house. This enables us to grind custom cutting tools, modify existing tools and regrind dull tooling with less lead time and better control over quality. Ability to grind all types of end mills, boring bars, reamers and special form tools such as slot cutters, lollipop, dovetail and porting tools. Cutting tool diameters from 5/64 up to 1-1/4” within tolerances of 0.00005” accuracy.

Grinding Equipment

- (1) ANCA – MX7 Linear

- (1) ANCA – FX5 Linear

Machines have linear motors that help to give superior finishes and zero backlash and better accuracy.

The MX7 Linear has a 6-pack wheel exchanger that allows for larger and more complex cutting tools. The FX5 has SCARA automation for long unattended run times of tools 3mm to 16 mm. It also has in-process laser measurement with SPC to track and maintain tool diameters during automation. With this machine, up to 30 hours of unattended time has been achieved.

Measurement

- (1) Eurotech – PG1000 4K

Gives us the capability to measure to 0.0001” at an adjustable magnification from 8x to 100x. Ability to see live images and import DXF files as an overlay for complex forms.

Laser Marking

- (1) Laser Marking Technologies – LMT – EcoBalt

Laser mark logo, tool number, and date on all special tooling that is ground for identification and traceability.

Wheel Truing

- (1) Advanced Super Abrasives – Ultra II

Abil

3D Printing

Acutec uses 3D printers in a variety of innovative ways:

- Inspection fixturing to produce low-cost high-quality holding fixtures to ensure repeatability and quick change set ups for measuring

- Wash fixturing to hold a batch of parts through ultrasonic wash

- Holding fixtures with embedded kevlar and carbon fiber for machining irregular castings and forgings

- Printing 3D models of parts for quoting and process engineering and validating prints.

- Printing the negative of a manifold to better understand hole intersections and tool paths

- Printing forgings for test machining to validate tool paths and fixturing tests at a low cost

- Printing ABS and ASA materials with a layer height down to .007”

3D Printers

- Ultimaker S5

- Markforged Markone Composite 3D printer 11 x 6 x 5

- Stratasys F120 printer 10 x 10 x 10

- MakerBot METHOD X Carbon Fiber Edition

Materials

- Nylon | PLA | Tough PLA | ABS | CPE | PVA | PC | TPU 95 | PP | Carbon filled ABS | Carbon filled Nylon

Strategic Partnerships

Acutec has partnered with an extensive network of outside service suppliers to meet the special process requirements common to aerospace parts. Acutec coordinates the processes of heat treat, shot peening, specialized coatings/plating, and others.

Outside service suppliers are selected based on customer directive, NADCAP accreditation, and their ability to meet or exceed quality and delivery standards.

Outside service suppliers are evaluated on a constant basis to ensure that quality and delivery requirements are met.

New part introduction includes a rigorous process, including APQP and FMEA to ensure the scope of work is clear and potential concerns are addressed timely and completely.